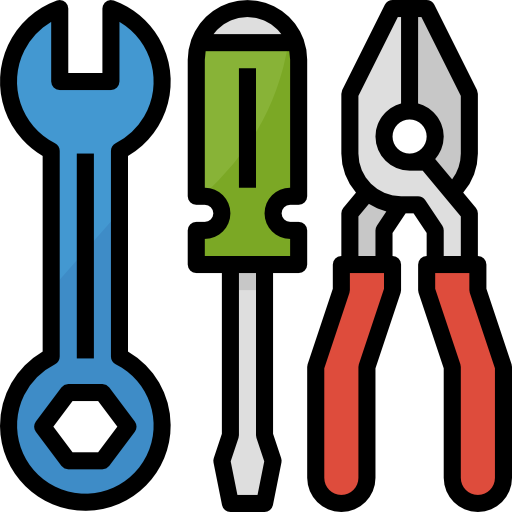

High-Precision Wire Cutter for Professional Use

The TNI-U (TU-2006) Wire Cutter is a high-performance tool designed to meet the rigorous demands of professionals and hobbyists alike. Whether you’re involved in electronics repair, circuit board assembly, or crafting electrical projects, this wire cutter delivers clean and consistent cuts every time. Engineered with quality materials and user-friendly ergonomics, the TU-2006 enhances both productivity and safety.

Durable Blades for Long-Term Use

The cutting edge of the TU-2006 is made from hardened carbon steel, ensuring long-lasting sharpness and resistance to wear. The precision-ground blades allow for smooth, flush cuts through soft copper wires, component leads, and fine cables. This minimizes the risk of short circuits and enhances the appearance of your work.

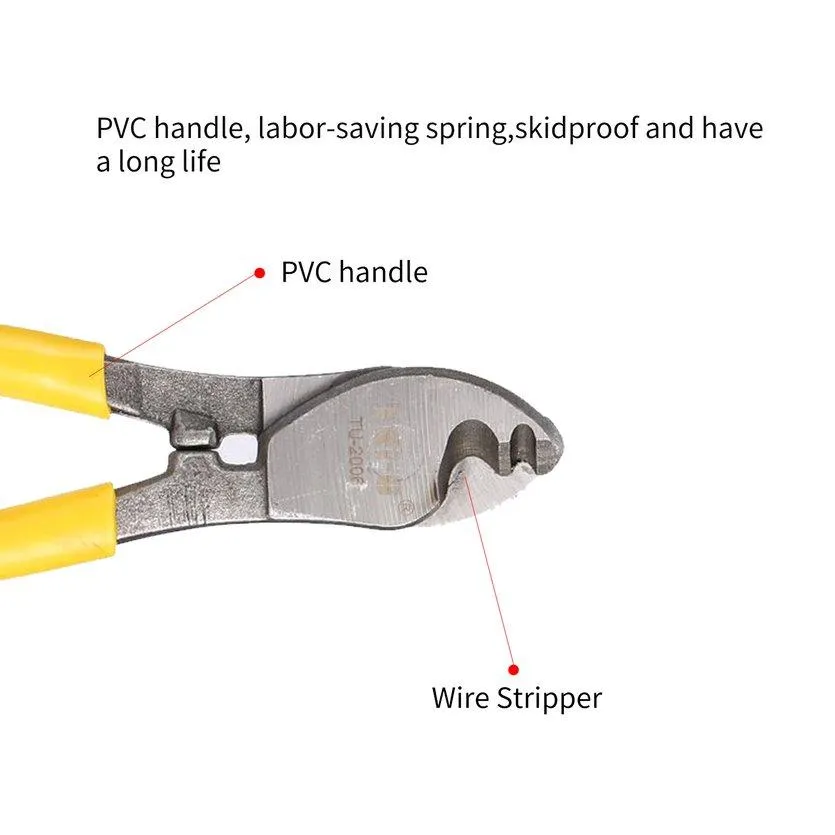

Ergonomic Design with Comfort Grip

Built with user comfort in mind, the TU-2006 features anti-slip PVC-coated handles that reduce strain during extended use. A spring-loaded mechanism provides automatic reopening of the jaws, significantly reducing hand fatigue and making repetitive cutting tasks easier and faster.

Compact Yet Strong

Despite its lightweight and compact design, this wire cutter is strong enough to handle daily tasks in workshop settings, laboratories, and educational environments. The size makes it ideal for tight spaces, such as inside control panels, small enclosures, or precision assemblies.

Key Features

Sharp carbon steel blades for clean and precise cuts

Flush cut capability ideal for electronics work

Ergonomic non-slip handle with spring-return mechanism

Lightweight and easy to maneuver

Ideal for copper wire, PCB leads, and small cable trimming

Product Specifications

| Specification | Detail |

|---|---|

| Product Name | Wire Cutter |

| Model | TNI-U (TU-2006) – |

| Blade Material | Hardened Carbon Steel |

| Handle Type | PVC Coated Ergonomic Handle |

| Spring Mechanism | Yes |

| Cutting Style | Diagonal / Flush Cut |

| Length | Approx. 130 mm |

Applications

Trimming leads of electronic components

Cutting soft copper and aluminum wires

Electrical repair and DIY projects

Assembly of control panels and PCBs

Robotics and prototyping